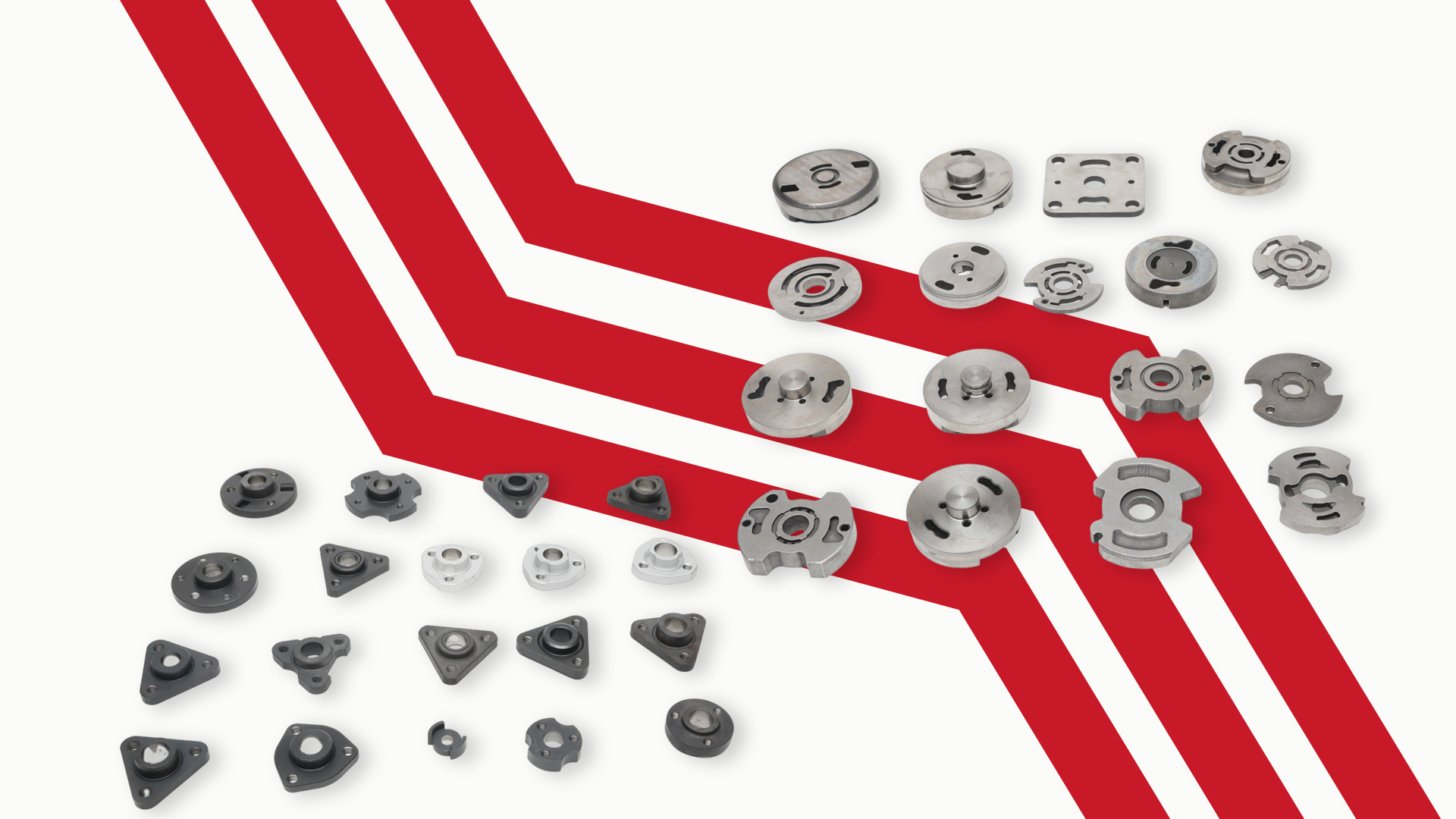

Product display

The company has a set of advanced powder metallurgy production equipment and technology at the same time the company attaches great importance to scientific and technological progress and new product development. We can also make all kinds of powder metallurgy molds and produce all kinds of powder metallurgy elements.

About Spirit Anchor

A manufacturer that provides various powder metallurgy elements and metallurgical molds for global customers.

Zhejiang Ling Anchor Powder Metallurgy Co., Ltd.

Zhejiang Lingchao Powder Metallurgy Co., Ltd. was formally established in 2005. Its predecessor was Diankou Powder Metallurgy Factory (established in 1996). It now has a production area of more than 50000 square meters and 160 employees. Our company mainly produces and sells powder metallurgy products: auto parts, construction machinery parts, textile machinery parts, cotton picker parts, electric and pneumatic tools and other products.

The company has been deeply engaged in the powder metallurgy industry for more than 30 years, producing various copper-based, iron-based, and stainless steel products. There are hundreds of existing production equipment, with an annual production capacity of more than 4000 tons of products, meeting customers' requirements for product size and performance At the same time, provide customers with product solutions, which can effectively shorten the production cycle and reduce production costs.

We sincerely hope to cooperate with friends in various industries. We will be pragmatic attitude, professional skills, to provide you with quality products and thoughtful service.

Time of establishment

Number of employees

Total production area

Annual production capacity of more than 4000 tons

Industry Solutions

Be a reliable product and a trustworthy partner.

Automotive field

Motorcycle field

Pneumatic tool field

Electric tools field

Mechanical field

Powder gold field

News

Understand real-time information, master the latest information in the application industry, and always strive to provide powder metallurgy solutions for global customers

2024-01-04

Powder metallurgy vibration screening ultrasonic transducer vibrator

National sales hotline 7*24 hours

No.8 Linganchor Road, Xiatangfan Industrial Zone, Diankou Town, Zhuji City